PRODUCT DETAIL

- Home / Product

- Durability

- Appearance

- Strength

- Sustainability

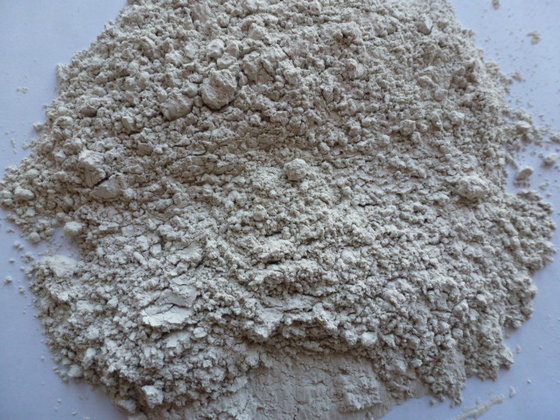

GGBFS SlAG

Ground-granulated blastfurnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a by-product of iron and steel-making) from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine powder. Ground-granulated blast fur-nace slag is highly cementitious and high in CSH (calcium silicate hy-drates) which is a strength enhancing compound which improves the strength, durability and appearance of the concrete.

Uses:

GGBS cement can be added to concrete in the concrete manufacturer’s batching plant, along with portland cement, aggregates and water. The normal ratios of aggregates and water to cementitious material in the mix remain unchanged. GGBS is used as a direct replacement for portland cement, on a one-to-one basis by weight. Replacement levels for GGBS vary from 30% to up to 85%. Typically 40 to 50% is used in most instances.

Benefits:

GGBS cement is routinely specified in concrete to provide protection against both sulfate attack and chloride attack. GGBS has now effectively replaced sulfate-resisting Portland cement (SRPC) on the market for sulfate resistance because of its superior performance and greatly reduced cost compared to SRPC.

In contrast to the stony grey of concrete made with Portland cement, the near-white color of GGBS cement permits architects to achieve a lighter colour for exposed fair-faced concrete finishes, at no extra cost. To achieve a lighter colour finish, GGBS is usually specified at between 50% to 70% replacement levels, although levels as high as 85% can be used. GGBS cement also produces a smoother, more defect free surface, due to the fineness of the GGBS particles. Dirt does not adhere to GGBS con-crete as easily as concrete made with portland cement, reducing mainte-nance costs.

Concrete containing GGBS cement has a higher ultimate strength than concrete made with Portland cement. It has a higher proportion of the strength-enhancing calcium silicate hydrates (CSH) than concrete made with Portland cement only, and a reduced content of free lime, which does not contribute to concrete strength. Concrete made with GGBS continues to gain strength over time, and has been shown to double its 28-day strength over periods of 10 to 12 years.

The optimum dosage of Ground granulated blast-furnace slag (GGBS) for replacement in concrete was reported to be 20-30% by mass to provide higher compressive strength compared to the concrete made with only cement.

Since GGBS is a by-product of steel manufacturing process, its use in concrete is recognized by LEED etc. as improving the sustainability of the project and will therefore add points towards LEED certification. In this re-spect, GGBS can also be used for superstructure in addition to the cases where the concrete is in contact with chlorides and sulfates. This is provid-ed that the slower setting time for casting of the superstructure is justified.